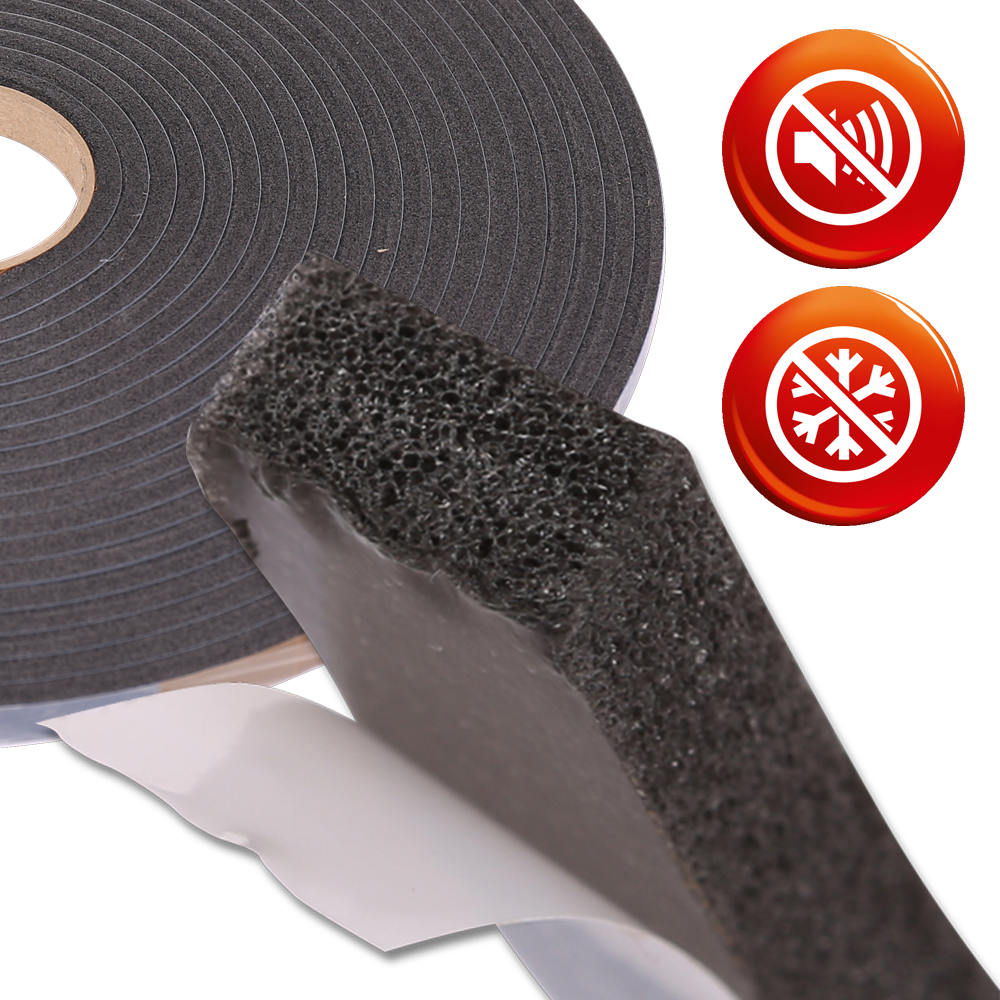

sponge rubber & Silicone sponge rubber

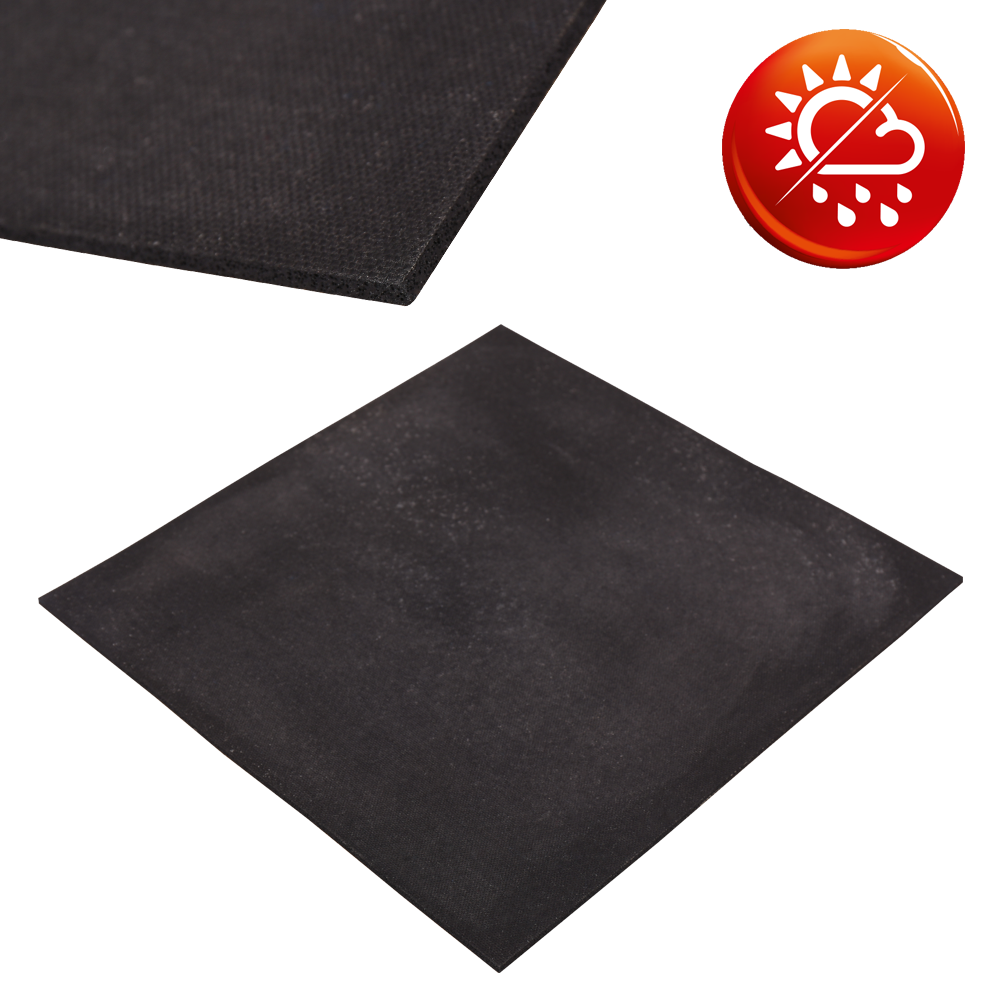

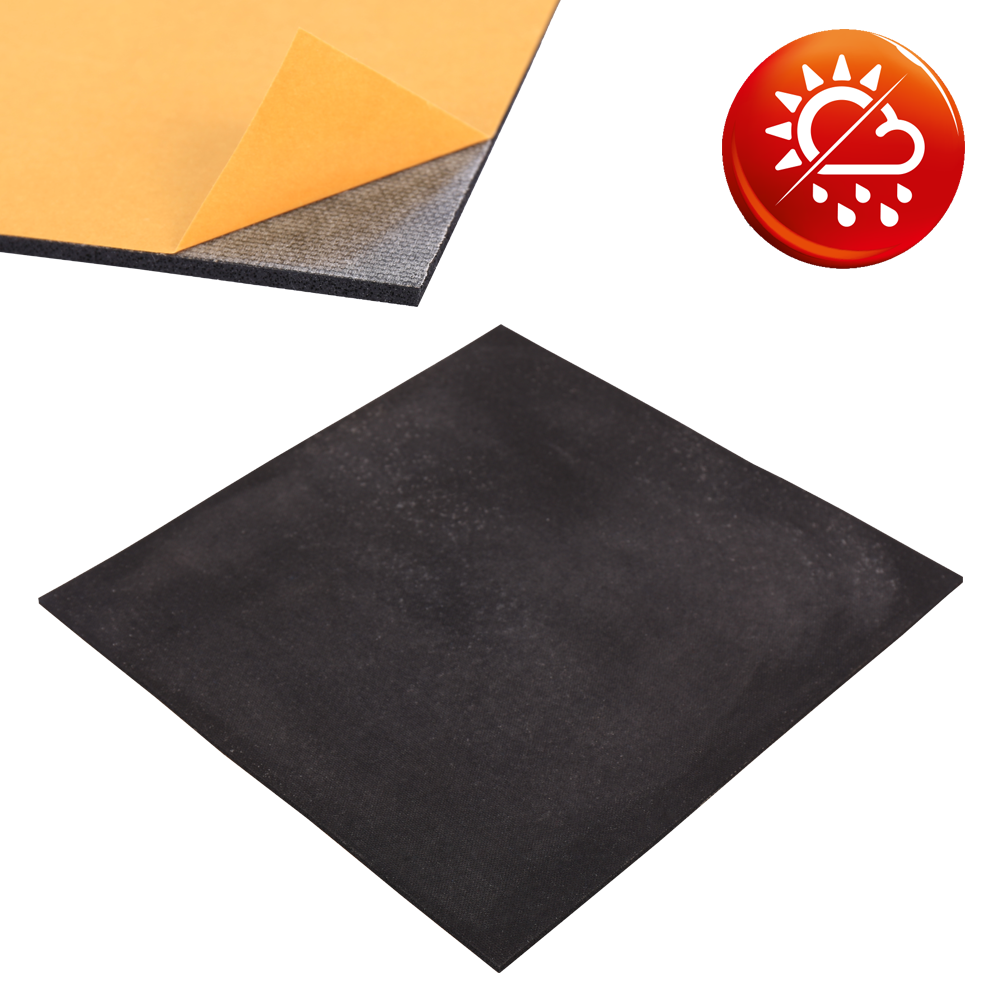

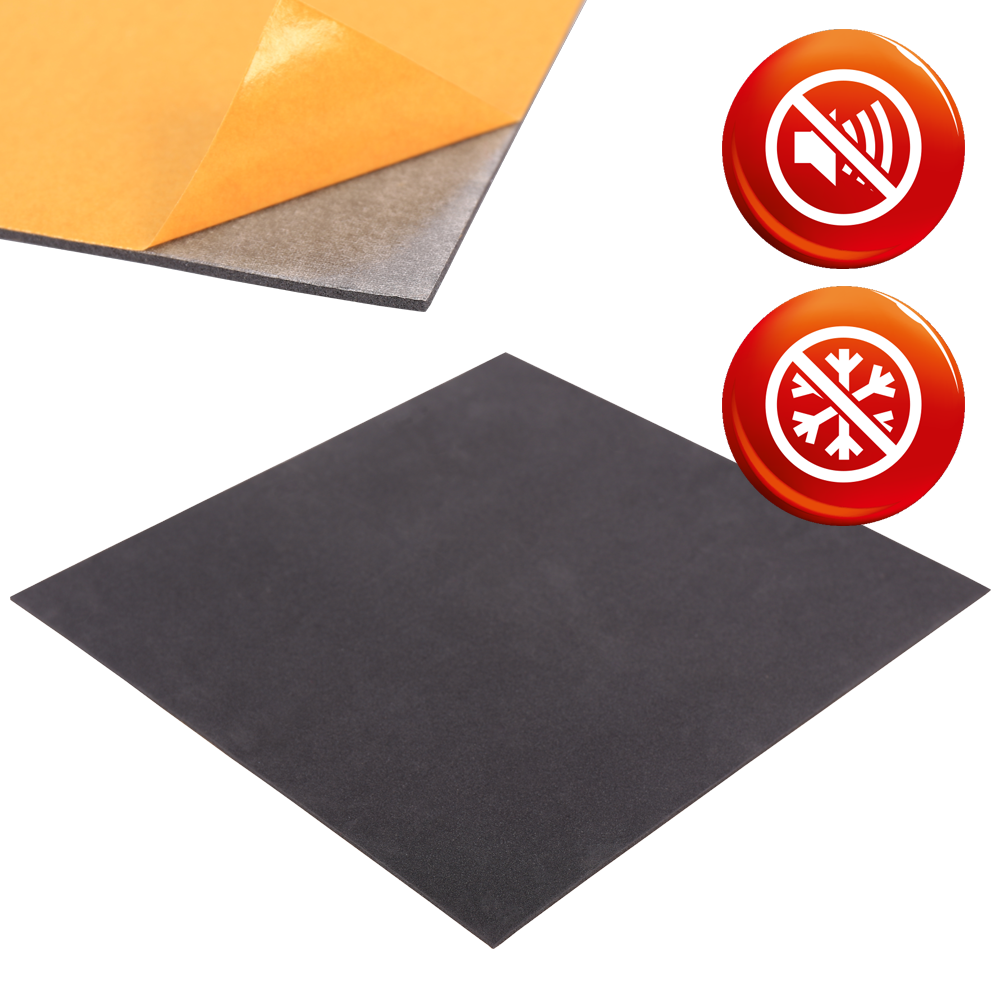

High quality sealing tapes & Sealing plates made of foam rubber with outer skin

sponge rubber & Silicone sponge rubber own in contrast to cellular ruber a high compressive elasticity and

a good resilience. Thus the material hugs itself tightly to

all surrounding surfaces even under light pressure and thus seals.

areas of application: Automotive, Construction, Electrical engineering, Air conditioning, aeronautics, Renewable Energies

square profile, extruded cords from EPDM sponge rubber

weather resistant (UV / ozone resistant)

age resistant

density: 500 kg/m³

resistant up to +110°C

sheets from NK sponge rubber

weather resistant (UV / ozone resistant)

acid resistant

density: 550 - 850 kg/m³

resistant up to +70°C

square profile from Viton (FKM sponge rubber)

oil resistant

weather resistant (UV / ozone resistant)

density: 950 kg/m³

resistant up to +250°C

products on request

square profile from Silicone sponge rubber

resistant to foodstuffs

oil resistant

density: 250 kg/m³

resistant up to +200°C

cellular ruber & PE foam

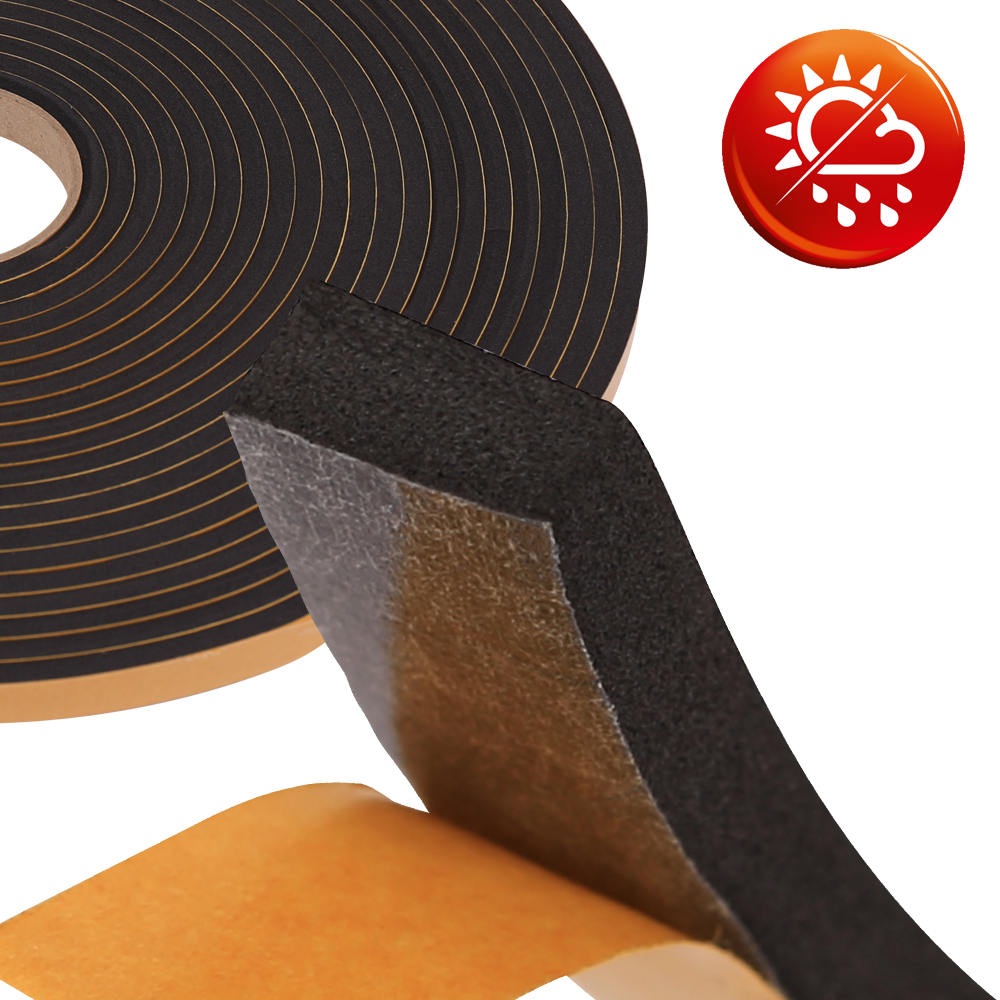

Versatile sealing tapes & Sealing plates made of closed-cell foam rubber

cellular ruber & PE foam are used successfully in all industrial sectors and is extremely versatile to process. cellular ruber is airtight and watertight and can be used as a seal. PE foam combines the positive properties of a plastic: high resistance to aging, high chemical resistance, odorless and heat deformable.

areas of application: Automotive, Construction, Electrical engineering, Air conditioning, Air conditioning, Medical technology, Renewable Energies, mechanical engineering, furniture construction, textile industry, Sports & Freetime

rolls, sheets from EPDM cellular ruber

weather resistant (UV / ozone resistant)

age resistant (long-lived)

density: 140 kg/m³

resistant up to +110°C

rolls, sheets from NBR cellular ruber

oil resistant

chemical resistant

density: 150 kg/m³

resistant up to +100°C

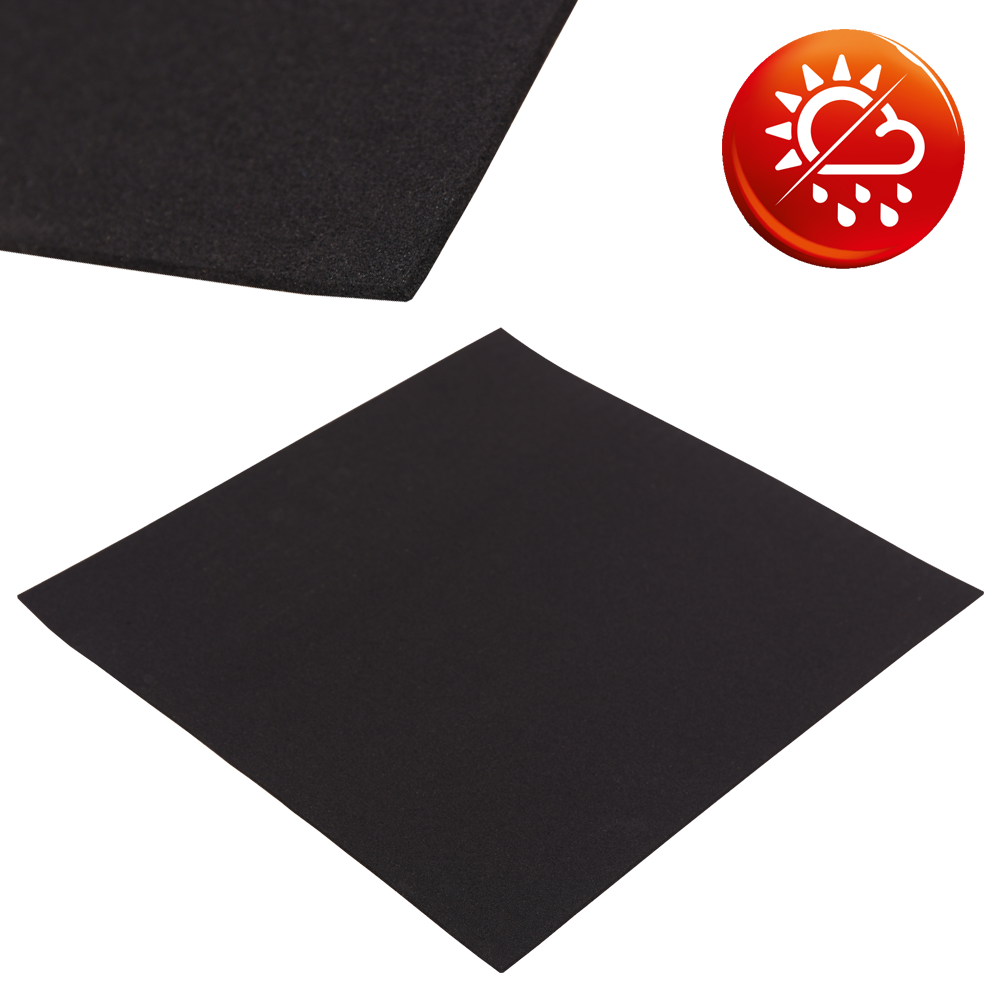

sheets, rolls from PE foam RG33

thermal insulation

age resistant (long-lived)

density: 33 kg/m³

resistant up to +100°C