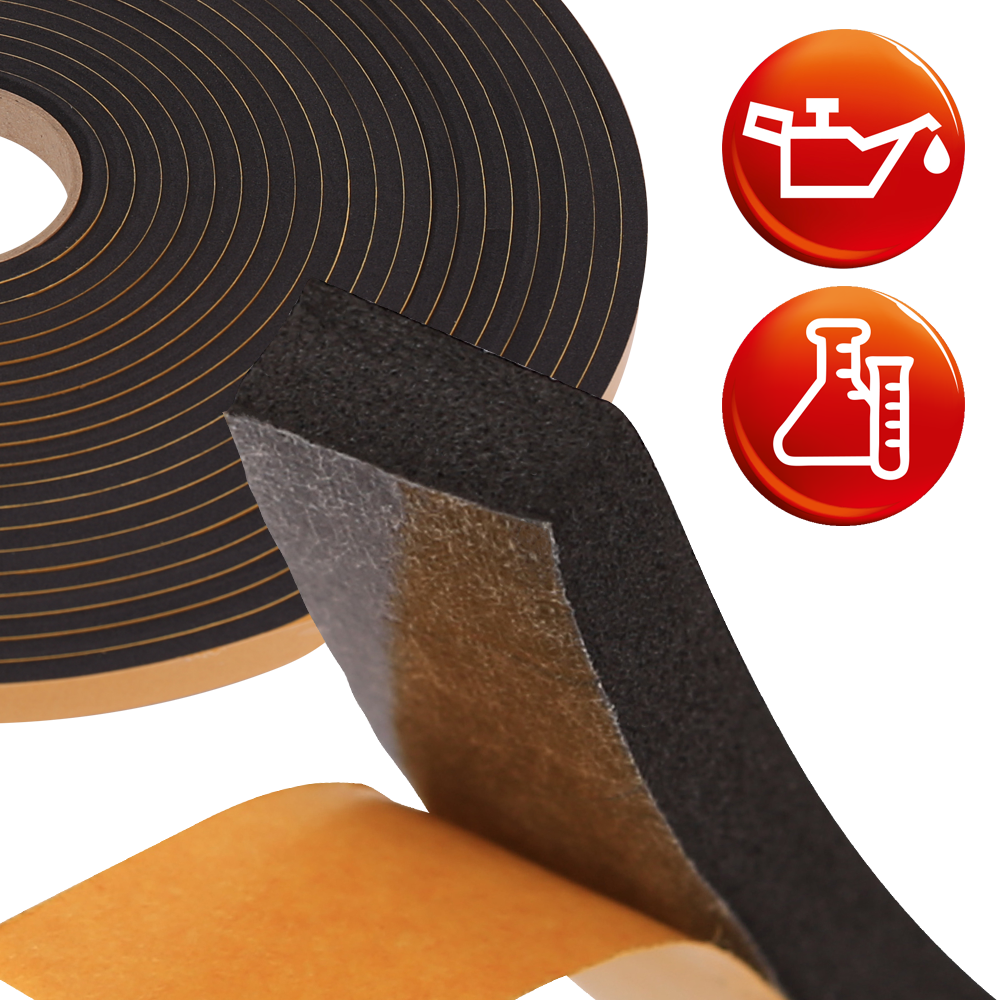

NBR cellular ruber black rolls adhesives

| Quantity | Unit price |

|---|---|

| To 19 |

€4.32*

|

| To 39 |

€4.05*

|

| To 59 |

€3.78*

|

| From 60 |

€3.51*

|

Available in 7 days, delivery time 1-3 days

Product information "NBR cellular ruber black rolls adhesives"

excellent oil resistance, chemical resistance & aging resistance (long-lived)

The NBR cellular rubber consists of acrylonitrile and butadiene (NBR) and Clorbutadiene rubber (CR) and is a rubber compound for many oil-resistant applications both indoors and outdoors. The cellular rubber is made into a foam in a special process (expansion) and has a closed cell structure without outer skin, making the material airtight and waterproof. The rubber compound is characterized by a very good oil resistance, weather resistance, ozone resistance and temperature resistance (up to + 100 ° C) and is extremely durable, due to the very good aging resistance. The resistance to animal and vegetable fats, fuels, and some chemicals is good to very good. The rubber compound is good flame retardant.

The cellular rubber is a foam in the commercial hardness or density and adapts under light pressure immediately and very well to uneven surfaces. The good recovery behavior (i.e., the material returns to its original shape) allows for optimal sealing. A compression of the material from 30% to max. 50% before sealing is recommended, with a compression of more than 50% damaging the material structure and greatly reducing the recovery behavior.

| adhesive: | one-sided self-adhesive |

|---|---|

| colour: | black |

| hardness: | very soft (until 30°Shore A) |

| material: | NBR cellular ruber |

| properties: | acid resistant, age resistant (long-lived), bases/alkali resistant, fire resistant, oil resistant, weather resistant (UV / ozone resistant) |

| working temprature range: | -40°C until +100°C |